The Key to Driving Profit in a Competitive Repair Market

In today’s competitive repair market, many bodyshops are prioritising the same key objective – getting more work through the door.

However, as any seasoned bodyshop manager will tell you – more repair volume doesn’t necessarily mean more profit. In fact, it can quickly lead to squeezed margins without a data-driven approach to managing different work categories.

As the landscape becomes more complex, it’s not just about increasing workload, it’s about increasing value. Understanding where time and resource are best invested is increasingly important for repairers looking to protect their margins.

Here we discuss why repair value trumps volume in today’s market, and how Onyx customers are maximising profitability with smarter, data-driven efficiency management.

Why repair profitability takes precedence in today’s market

While getting work through the door is always going to be the imperative for repairers, in today’s increasingly complex market, it’s never been more critical to ensure this work delivers the most value possible.

More work categories, more complexity

The increasing technological complexity of many repairs, rising cost of parts, as well as increased appetite for ‘repair over replace’ are leading to a more diverse pool of requirements, and costs, than ever before.

This makes it harder to maintain profitability across different work categories, without the right data & oversight to understand their unique complexities, common exceptions, and the bottom-line value they provide.

It’s therefore essential that repairers are not just focused on attracting work, but attracting the right work to maintain their margins, and managing it in a way that promotes maximum value, minimal leakage.

How to drive more profit from every repair

To improve profitability in today’s market, repairers must focus on three interlinked areas: controlling costs, boosting productivity, and ensuring work delivers value.

While repairers may not always have the liberty of choice when it comes to the types of work they accept, there are steps they can take to maximise its value, identify leakage, and recover unnecessary costs.

Here’s how repairers can maximise profitability across every job, at a time where staying ahead of margins has never been more imperative.

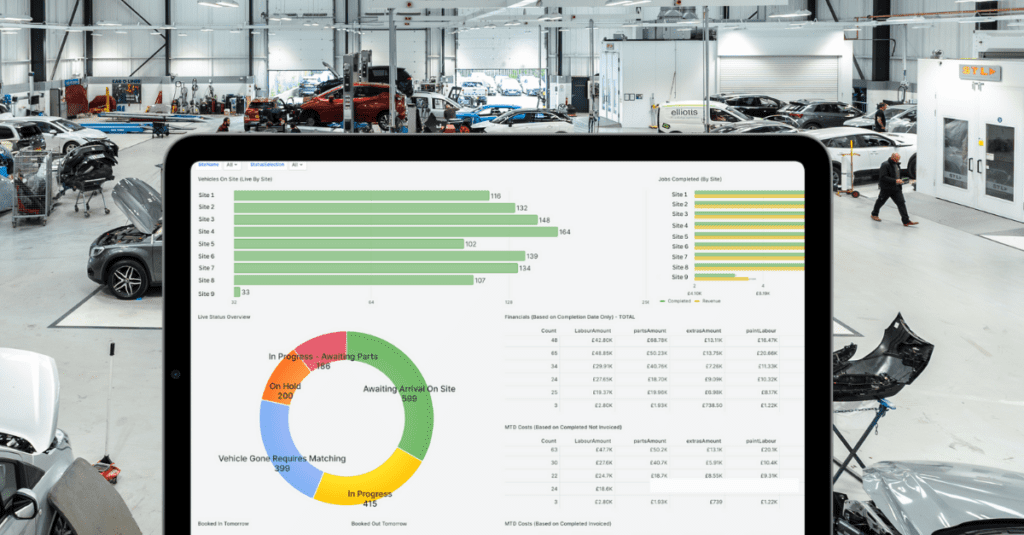

Understand which jobs drive value, and which don’t

“We’ve worked with repairers who’ve now started analysing the cost and efficiency of each work category more closely. In doing so, they’ve been able to clearly identify where the strongest margins sit, and equally which types of work consistently apply pressure to resource. That level of visibility has helped them make more informed decisions about the work they prioritise getting over the line day-to-day.” – Pete Thompson, Managing Director, Onyx Repair Innovations

Use repair over replace practices optimally

“Several of our customers have told us that by reviewing real-time parts availability and using Onyx’s parts interceptor, they’ve been able to make better decisions around using green or aftermarket parts, where allowed by the work provider or customer. This insight helps them avoid missed opportunities to reduce costs, and refine where repair-over-replace genuinely delivers value.”

Use real-time visibility to keep jobs on track

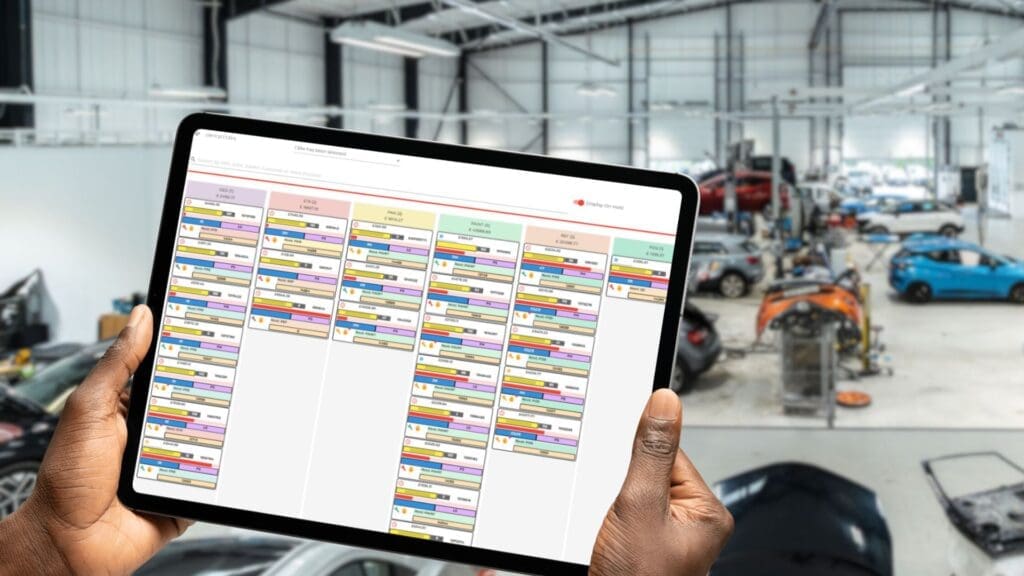

“By using real-time visibility through the Onyx technician app and task tracker, repairers can monitor progress across the workshop and act quickly if jobs fall behind. This live insight helps keep workflows on track and ensures effort is going where it delivers most value, without relying on guesswork or retrospective reports.”

Use data to reclaim and control costs

“Repairers are increasingly using Onyx to control job costs in real-time, particularly around labour allocation and parts. The ability to track time against the estimate ensures work doesn’t exceed what’s approved or billable, and Onyx’s actual-vs-estimate matching gives instant visibility into where profit may be leaking. This level of control helps ensure every cost aligns with the job, and nothing gets missed off the invoice.”

Centralise Parts & Inventory – and Catch Missed Discounts

“Managing parts across multiple suppliers used to be time-consuming and hard to track. Now, many customers are using Onyx to centralise the management of parts, tracking availability, backorder status, and – crucially – whether expected discounts are being met. Several customers have flagged suppliers who weren’t applying agreed terms, thanks to the insight they now get at the point of receipting.”

Save time by eliminating unnecessary admin

“Many of the repairers we work with have been able to significantly reduce admin time by moving onto Onyx – from the office to the workshop floor. By using automations, and our fully-connected technician app, they’re centralising decision-making and streamlining everything from estimating, to task management, to invoicing – and removing the need to switch between platforms or re-key admin work. This makes a big difference in enabling frontline staff to focus on repairs and their quality, not admin or data entry.”

Drive profitability, performance, and oversight with Onyx

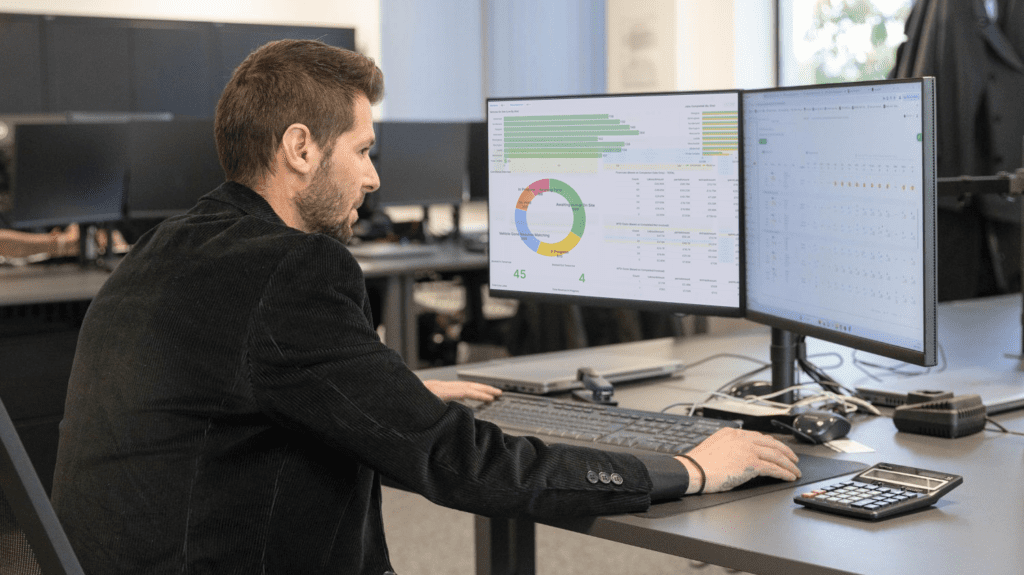

By focusing on cost control, productivity, and profitability, repairers can protect their margins and grow sustainably, even in a high-pressure environment. Onyx BMS provides the insight layer that makes this kind of control possible.

Popular Posts

-

Onyx Repair Innovations and BodyNet Join Forces

Onyx Repair Innovations and BodyNet have announced that they are coming together to form a single business, combining their expertise to deliver a connected suite of repair and estimating systems forbodyshops. The move follows Activate Group’s acquisition of Avant Group, which has brought the BodyNet and Onyx businesses together under one ownership structure. Onyx Repair…

-

The Key to Driving Profit in a Competitive Repair Market

In today’s competitive repair market, many bodyshops are prioritising the same key objective – getting more work through the door. However, as any seasoned bodyshop manager will tell you – more repair volume doesn’t necessarily mean more profit. In fact, it can quickly lead to squeezed margins without a data-driven approach to managing different work…

-

A chat with Hayley Avory: Implementation and Training Specialist at Onyx

Transitioning to a new bodyshop management system can feel daunting, but having the right support makes all the difference! At Onyx, we support a smooth transition, with dedicated implementation and training tailored to each repairer’s needs. To share more on this, we caught up with Hayley Avory, Implementation and Training Specialist at Onyx, to learn…

Leave a Reply