A chat with Hayley Avory: Implementation and Training Specialist at Onyx

Transitioning to a new bodyshop management system can feel daunting, but having the right support makes all the difference! At Onyx, we support a smooth transition, with dedicated implementation and training tailored to each repairer’s needs.

To share more on this, we caught up with Hayley Avory, Implementation and Training Specialist at Onyx, to learn about her career journey and how she helps repairers get the most out of the Onyx Bodyshop Management System.

Interview with Hayley Avory, Onyx BMS:

Tell us a bit about your career before joining Onyx Repair Innovations

Before joining Onyx, I worked in the telecommunications industry, as a second line engineer, supporting customers using our managed services. Along the way, I had the chance to work as the subject matter expert on several projects, and that’s when I discovered how much I enjoyed creating better ways of working and seeing the difference it could make. That experience inspired me to start my journey in project management. First as a Business Analyst and then as a Project Manager, where I could combine my technical background with my passion for delivering projects and training customers.

How do you think Onyx BMS is transforming day-to-day repairer processes?

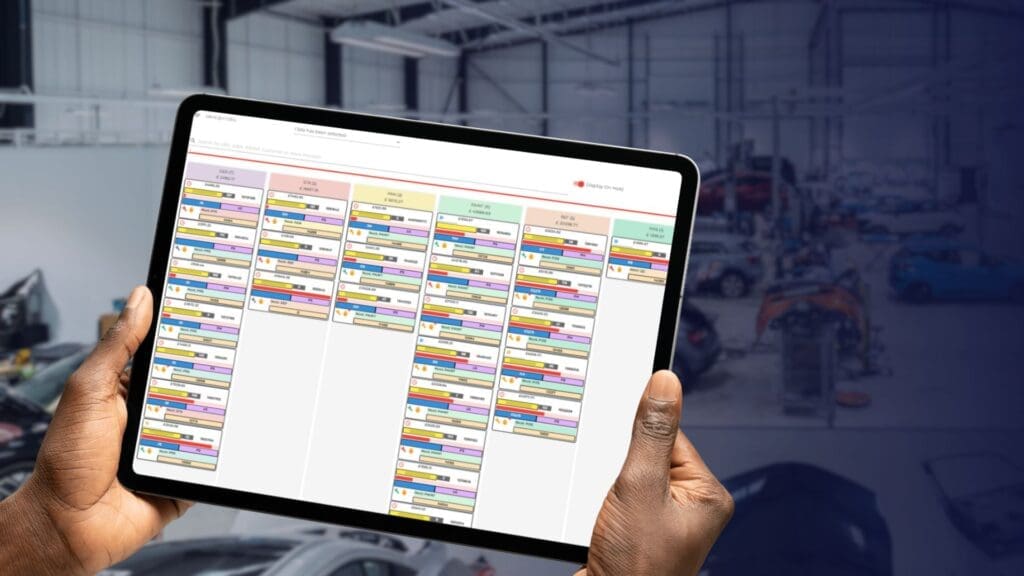

Onyx BMS is transforming day-to-day repairer process by bringing key tasks into one easy-to-use platform, streamlining workflows from job allocation to completion. It removes the need for multiple systems, providing real-time visibility of job status, and ensuring accurate data is captured at every stage. This not only reduces admin time but also helps repairers work more efficiently, improve turnaround times, and deliver a better experience for customers.

What Onyx BMS features do repairers you interact with find most helpful?

In my experience, repairers really like the fact that the Task Tracker gives them real-time data – they can see exactly who is working on each task and what stage it’s at. This visibility helps them prioritise their workload, reduce delays, and keep everything moving smoothly without having to chase for information.

How long does it usually take to implement Onyx BMS?

Depending on the size of the repairer, it usually takes two to three days to fully implement Onyx BMS at a new site. We handle much of the setup work in advance to ensure go-live runs as smoothly as possible, allowing us to focus entirely on training while on site.

What does the implementation process usually look like?

Leading up to the implementation, I work closely with the repairer to ensure their new Onyx tenant is fully set up and tailored to their needs before go-live. This includes everything from initial configuration and data population to system testing and setting up user access. I also make sure detailed demos of the Onyx system are provided, so all users are familiar with its layout and capabilities. As part of this process, I carry out a review of their current processes to confirm they have everything they need for a successful go-live. I then deliver training either on-site or online, depending on their requirements.

What are the main questions technicians have when being introduced to Onyx BMS?

The main questions technicians ask usually relate to adjusting to a fully paperless process. While they find the Tech app very easy to use, moving away from paper can be challenging, so most of their questions focus on how to complete tasks and access information digitally. We make the transition smoother with hands-on training, so technicians quickly feel confident using the app.

What do you think are the biggest considerations for bodyshops today?

Balancing insurer demands with profitability. Insurer SLAs on cost, timelines, and parts can provide steady work but often squeeze margins. Bodyshops must meet these demands while covering the rising costs of training, equipment, and compliance to stay profitable.

Onyx supports repairers in meeting these challenges by streamlining processes, improving efficiency, and delivering greater control over performance and profitability.

Book your Free Onyx BMS Demo:

Discover Onyx BMS, the next-generation Bodyshop Management System for modern repair shops. Full mobile usability, real-time visualised cost & performance insights, and intuitive task-driven automations to streamline your entire repair management process.

Discover how our Next-Generation Bodyshop Management System is helping repairers achieve consistency, insight, and automation across every step of their repair process – and keep their technicians on task at every stage.

Book your free BMS demo today:

Popular Posts

-

Onyx Repair Innovations and BodyNet Join Forces

Onyx Repair Innovations and BodyNet have announced that they are coming together to form a single business, combining their expertise to deliver a connected suite of repair and estimating systems forbodyshops. The move follows Activate Group’s acquisition of Avant Group, which has brought the BodyNet and Onyx businesses together under one ownership structure. Onyx Repair…

-

The Key to Driving Profit in a Competitive Repair Market

In today’s competitive repair market, many bodyshops are prioritising the same key objective – getting more work through the door. However, as any seasoned bodyshop manager will tell you – more repair volume doesn’t necessarily mean more profit. In fact, it can quickly lead to squeezed margins without a data-driven approach to managing different work…

-

A chat with Hayley Avory: Implementation and Training Specialist at Onyx

Transitioning to a new bodyshop management system can feel daunting, but having the right support makes all the difference! At Onyx, we support a smooth transition, with dedicated implementation and training tailored to each repairer’s needs. To share more on this, we caught up with Hayley Avory, Implementation and Training Specialist at Onyx, to learn…

Leave a Reply